Oxidation capacitors are a type of capacitor that is specifically designed to withstand high temperatures and harsh environments. They are commonly used in industrial applications where extreme conditions are present, such as in automotive, aerospace, and military applications. In this article, we will explore the product features of oxidation capacitors and how they differ from other types of capacitors.

Another important feature of oxidation capacitors is their resistance to harsh environments. These capacitors are designed to withstand exposure to moisture, chemicals, and other contaminants that can damage traditional capacitors. This makes them ideal for use in outdoor applications or in environments where exposure to harsh conditions is common.

Oxidation capacitors also have a longer lifespan than traditional capacitors. The materials used in their construction are more durable and resistant to degradation over time, which means that they can last for many years without needing to be replaced. This can save time and money in the long run, as frequent capacitor replacements can be costly and time-consuming.

In addition to their durability and resistance to harsh environments, oxidation capacitors also offer excellent electrical performance. They have low ESR (equivalent series resistance) and high ripple current ratings, which means that they can deliver a stable and reliable electrical signal even in demanding applications. This makes them ideal for use in power supply circuits, motor drives, and other high-performance applications.

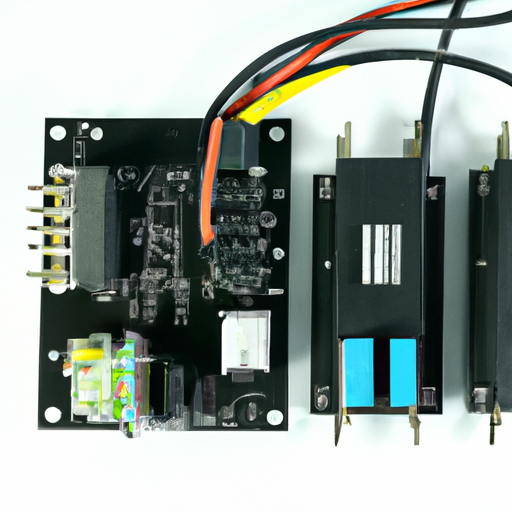

One of the key differences between oxidation capacitors and other types of capacitors is their construction. Oxidation capacitors are typically made with a special type of electrolyte that is designed to withstand high temperatures and harsh environments. This electrolyte is often a solid-state material, such as tantalum or aluminum oxide, that is less prone to leakage or degradation than the liquid electrolytes used in traditional capacitors.

Another important feature of oxidation capacitors is their compact size. Despite their high temperature and high performance capabilities, oxidation capacitors are typically smaller and lighter than traditional capacitors. This makes them ideal for use in applications where space is limited or weight is a concern, such as in automotive or aerospace applications.

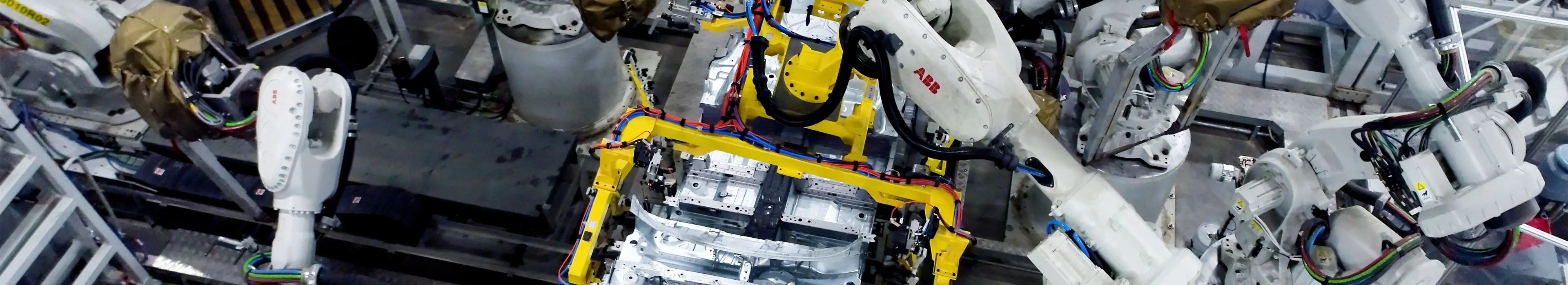

Overall, oxidation capacitors offer a unique combination of high temperature resistance, durability, and electrical performance that make them ideal for use in a wide range of industrial applications. Whether you are designing a power supply for a high-performance motor drive or a control system for a military vehicle, oxidation capacitors can provide the reliability and performance you need to ensure your system operates smoothly and efficiently.

In conclusion, oxidation capacitors are a versatile and reliable component that can be used in a wide range of industrial applications. Their high temperature resistance, durability, and electrical performance make them ideal for use in demanding environments where traditional capacitors may not be able to withstand the conditions. If you are looking for a capacitor that can deliver high performance in extreme conditions, oxidation capacitors may be the perfect solution for your application.