Signal converters are essential components in various electronic devices and systems, as they help in converting one type of signal into another. This conversion process is crucial for ensuring compatibility between different devices and systems, allowing them to communicate effectively with each other. In this article, we will explore the mainstream production process of signal converters, highlighting the key steps involved in their manufacturing.

The production process of signal converters typically begins with the design and planning phase. During this stage, engineers and designers work together to develop a detailed blueprint of the converter, outlining its specifications, features, and functionality. This design phase is crucial for ensuring that the final product meets the required performance standards and specifications.

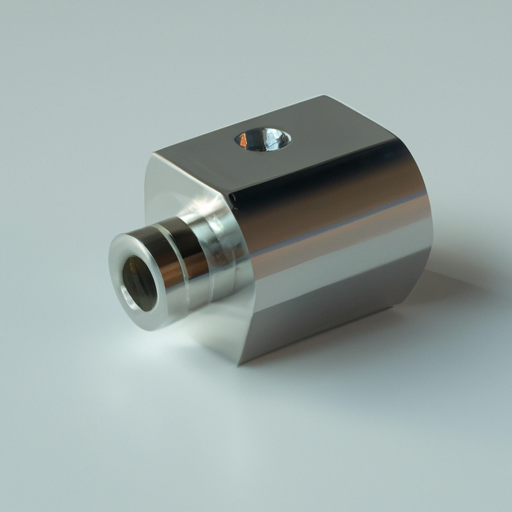

2. Component Selection:

Once the design phase is complete, the next step in the production process is the selection of components. Signal converters are made up of various electronic components, such as resistors, capacitors, transistors, and integrated circuits. These components are carefully selected based on their quality, performance, and compatibility with the design specifications.

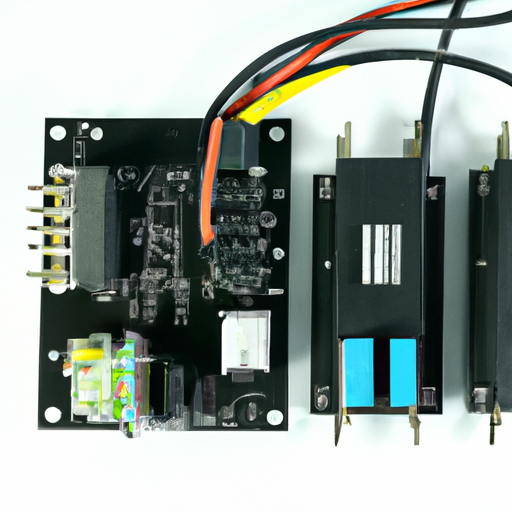

3. PCB Layout:

After the components are selected, the next step is to create the printed circuit board (PCB) layout for the signal converter. The PCB layout is a crucial step in the production process, as it determines the physical arrangement of the components on the board and the electrical connections between them. The PCB layout is typically created using computer-aided design (CAD) software, which allows engineers to optimize the layout for performance and efficiency.

4. Assembly:

Once the PCB layout is finalized, the next step is the assembly of the signal converter. This involves soldering the electronic components onto the PCB, following the layout design. The assembly process is typically carried out using automated assembly machines, which ensure precision and accuracy in the placement of components. After the components are soldered onto the PCB, the board is inspected for any defects or errors.

5. Testing and Quality Control:

After the assembly is complete, the signal converter undergoes rigorous testing and quality control procedures to ensure that it meets the required performance standards. Various tests are conducted, such as functional testing, electrical testing, and environmental testing, to verify the functionality and reliability of the converter. Any defects or issues identified during testing are addressed and corrected before the final product is released for production.

6. Packaging and Shipping:

Once the signal converter has passed all quality control tests, it is then packaged and prepared for shipping. The packaging process involves placing the converter in protective packaging, such as boxes or trays, to ensure that it is not damaged during transportation. The packaged converters are then shipped to distributors, retailers, or end-users, depending on the distribution channel.

In conclusion, the production process of signal converters involves several key steps, including design and planning, component selection, PCB layout, assembly, testing, and packaging. Each of these steps is crucial for ensuring the quality, performance, and reliability of the final product. By following a systematic and well-defined production process, manufacturers can produce high-quality signal converters that meet the needs and requirements of their customers.